As the successor of the chemistry arm of the Gockel Company, the G.IN.SER GmbH looks back at more than 35 years of experience in the treatment of circulation systems, which are part of paper machines. The task is to solve problems caused by sedimentation, slime and odour. The G.IN.SER Company also provides preservation solutions for the paper making and processing industries.

|

IntroductionIt is no secret that the circulating water in a paper machine contains enough nutrients for the growth of all kinds of micro-organisms. Plenty of information exists on the different growth conditions for micro-organisms and the damage to fibres and auxiliary materials, which may be caused by micro-organisms. Micro-organisms are also co-responsible for the sediment formation, unpleasant odours and corrosion. A Brief ReviewIn the early 1950s, the paper industry started using fast running paper machines to satisfy the demands of the booming newspaper business. Fibre recovery facilities necessitated the first compression of the water circulation system. Stainless steel and plastic pipes replaced copper and iron pipes. Plastic screens would soon be used instead of the old bronze screens. With the introduction of these innovations the problems caused by biological sludge increased. The innovations changed various parameters in favour of microbial growth.

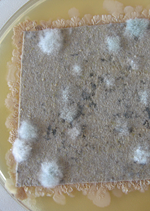

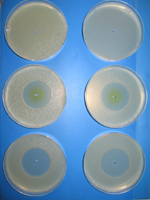

In summary, if the system runs with high fresh water demand, low temperature of the circulating water and at a low pH (acidic), mostly aerobic bacteria and mould will grow. In a closed water circulation system at a neutral pH and higher temperature, predominantly anaerobic bacteria and yeast will grow. BIOCIDE USE In recent years, most paper mills adapted the maintenance

treatment regimens to their paper machine's circulation

system. This usually ensures trouble-free paper machine runs.

Still, the biocide dosages must be adapted to changing

requirements and process management modalities to ensure the

sustained efficacy of the biocide treatment. |